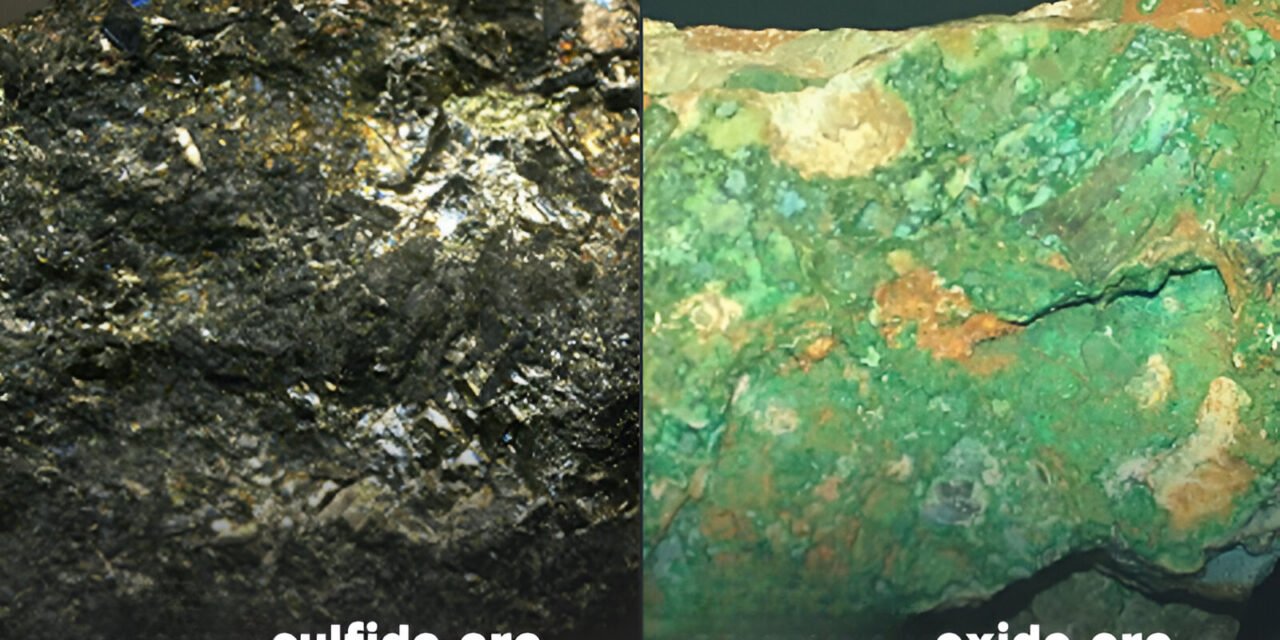

The processing of oxide ores differs significantly from sulfide ores in metal extraction due to the chemical properties, reactivity, and mineral composition of the two types of ores. The differences in processing methods primarily stem from the differences in the way these ores behave during extraction and the methods required to separate the valuable metals from gangue (waste materials).

1. Chemical Composition and Reactivity

- Oxide Ores: These ores contain metals in their oxidized form, where oxygen is chemically bonded to the metal, making them relatively stable. Examples of oxide ores include hematite (Fe₂O₃) for iron, bauxite (Al₂O₃·2H₂O) for aluminum, and gibbsite for aluminum.

- Characteristics: Oxide minerals are generally stable and less reactive compared to sulfide ores. The metals in oxide ores are often present as non-metallic oxides and require processes like smelting or hydrometallurgy (leaching) to extract the metal.

- Sulfide Ores: These ores contain metals in combination with sulfur (e.g., chalcopyrite (CuFeS₂) for copper, galena (PbS) for lead, and sphalerite (ZnS) for zinc), and they tend to be more reactive due to the presence of sulfur.

- Characteristics: Sulfide minerals are generally less stable and can be easily oxidized in the presence of oxygen, especially in wet or humid conditions. Sulfide ores typically require roasting or smelting to convert the metal into its oxidized form before extraction.

2. Smelting vs. Leaching

- Oxide Ores: In many cases, oxide ores are processed using hydrometallurgical techniques:

- Leaching: Oxide ores are often dissolved in an acid or base, where the metal is separated from the gangue. For example:

- Bauxite is treated with sodium hydroxide to separate alumina from silica and other impurities.

- Copper oxide ores can be leached with sulfuric acid, and the resulting copper sulfate solution is further treated to recover copper.

- Solvent Extraction and Electrowinning (SX/EW): These are used in cases like copper extraction, where the metal is dissolved in a solvent, then electrowinning deposits the metal onto a cathode.

- Leaching: Oxide ores are often dissolved in an acid or base, where the metal is separated from the gangue. For example:

- Sulfide Ores: Sulfide ores require pyrometallurgical methods, such as roasting and smelting, due to the sulfur content:

- Roasting: In roasting, sulfide ores are heated in the presence of oxygen to remove sulfur, creating metal oxides (e.g., CuO for copper) that can then be reduced to the metal.

- Smelting: This involves heating the metal oxide (from roasting) in a furnace with a reducing agent (like carbon) to produce the metal.

- Example: Copper sulfide ores are roasted to produce copper oxide, which is then reduced using carbon in a smelting furnace.

3. Environmental Considerations

- Oxide Ores:

- Oxide ores generally produce fewer toxic by-products compared to sulfide ores. However, acid mine drainage and emission of CO₂ during processes like smelting still need to be managed.

- Alkaline and acid leaching methods also require careful waste management, particularly in the case of bauxite or copper leaching, to avoid contamination of surrounding water sources.

- Sulfide Ores:

- The roasting of sulfide ores releases sulfur dioxide (SO₂), which must be controlled to prevent air pollution.

- Acid mine drainage (AMD) is a significant environmental issue for sulfide mining. When sulfides are exposed to oxygen and water, they oxidize, forming sulfuric acid and releasing toxic metals like arsenic and cadmium into the environment.

4. Metal Recovery and Ore Grade

- Oxide Ores: Oxide ores tend to be lower-grade compared to sulfide ores, meaning they contain a lower concentration of the desired metal per ton of ore. However, oxide ores are often easier to process once they are concentrated.

- Oxide ores can also be easily leached using acidic or alkaline solutions, resulting in a relatively high recovery rate for metals such as aluminum, iron, gold, and copper.

- Sulfide Ores: Sulfide ores often have higher grades, but they require more intensive and complex processing (e.g., roasting and flotation) to separate the metal from sulfur.

- The sulfur content in sulfide ores can complicate the extraction process and increase the need for sulfur removal, but sulfides generally offer better metal recovery.