The properties of clay minerals—such as particle size, plasticity, and cation exchange capacity (CEC)—are critical in determining how the clays are processed, their suitability for various applications, and the efficiency of beneficiation techniques. Here’s how each of these properties impacts clay mineral processing:

1. Particle Size

Impact on Processing:

- Finer particles (less than 2 microns) typically have higher surface areas, which can influence both their behaviors during processing and their end-use properties.

- Coarse clays (larger particles) may need to undergo size reduction processes, such as grinding or milling, to achieve the desired particle size for specific applications like ceramics, coatings, or drilling fluids.

Processing Techniques:

- Wet screening and hydraulic classification are often used to separate finer particles from coarser ones.

- For clays with fine particle sizes, flotation or gravity separation may become less effective, requiring additional steps like chemical leaching or magnetic separation.

- Fine clays tend to have higher surface area, which may necessitate additional flocculation or dispersion treatments when mixing with other materials.

Application Impact:

- In ceramics, smaller particle sizes are usually desired for smooth surfaces and higher quality finishes, whereas larger particles may be better for applications requiring more strength or rigidity.

- Smaller particles in drilling muds improve the flow and performance, while in paint or paper production, smaller sizes may result in better smoothness and opacity.

2. Plasticity

Impact on Processing:

- Plasticity refers to the ability of clay to deform without cracking, which is influenced by the mineral composition and the water content in the clay. High plasticity clays, like those rich in montmorillonite, can be more challenging to process, especially when drying or shaping, as they are more prone to shrinkage and cracking.

- Low plasticity clays, like kaolinite, are easier to work with during processes like molding, forming, and extrusion because they do not shrink as much upon drying.

Processing Techniques:

- Plastic clays may require additional steps such as dewatering, flocculation, or drying to reduce their plasticity before being shaped or further processed.

- High plasticity clays may require sieving to remove coarse particles or other impurities that contribute to undesirable characteristics during processing.

- For low plasticity clays, the process of mixing with additives (such as binders or fluxes) may be necessary to improve their moldability.

Application Impact:

- High plasticity is highly desirable in industries like brick making, where clays are shaped and then fired. The ability to retain shape during drying and firing is crucial for creating uniform and durable products.

- Low plasticity clays are ideal for uses such as ceramics, paints, or paper coatings, where high moldability or less shrinkage is required.

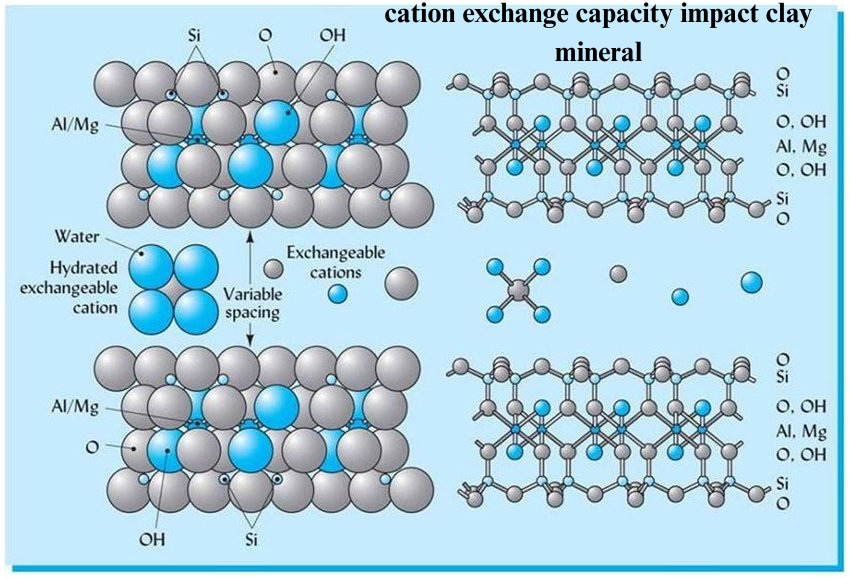

3. Cation Exchange Capacity (CEC)

Impact on Processing:

- CEC refers to the ability of clay to exchange positively charged ions (cations) with those in the surrounding environment, and it plays a key role in determining how the clay interacts with other substances during processing.

- Clays with high CEC, such as montmorillonite and other smectites, are more reactive and can hold onto larger amounts of water and metal ions, which can affect the viscosity and swelling behavior of the clay.

Processing Techniques:

- High CEC clays require additional steps such as activation or swelling control when used in certain applications (e.g., drilling fluids or binding agents).

- Exchanging cations in high-CEC clays can also be beneficial for ion-exchange applications, such as in water purification or as adsorbents.

Application Impact:

- Clays with high CEC, such as bentonite, are commonly used in drilling fluids, where the ability to exchange ions helps control viscosity and enhance the clay’s ability to suspend cuttings.

- In ceramics and pottery, high CEC can affect the firing and shaping process, as it impacts the clay’s interaction with other components.

- In agriculture, clays with high CEC are valued for their ability to retain nutrients and moisture in soil amendments.