Silicate minerals are crucial in sustainable and eco-friendly construction and industrial applications due to their abundance, durability, and versatility. These minerals are often incorporated into various products that promote resource efficiency, energy savings, and environmental conservation. Below are some of the ways silicate minerals are used sustainably in construction and industrial sectors:

1. Sustainable Construction Materials

- Cement and Concrete:

- Silicate minerals, such as limestone (calcium carbonate), clay, and sand, are key ingredients in the production of cement and concrete.

- Eco-friendly production: The use of blended cements (which incorporate fly ash, slag, and silica fume) reduces the carbon footprint of cement production by replacing a portion of the clinker with lower-carbon materials.

- Benefits: Silicate-based cement has excellent durability, fire resistance, and strength, making it suitable for sustainable building projects that last longer and require fewer repairs.

- Geopolymer Concrete:

- Geopolymers, made from alkali-activated silicate minerals (e.g., fly ash, metakaolin, and slag), are an alternative to traditional concrete. They emit lower CO₂ and have high thermal stability and resistance to chemicals.

- Eco-benefit: By using industrial by-products like fly ash and slag, geopolymer concrete contributes to waste recycling and reduces reliance on Portland cement.

2. Insulation Materials

- Glass Wool and Mineral Wool:

- Silica-based materials such as glass wool and mineral wool (made from basalt or slate) are used for thermal and acoustic insulation in buildings.

- Sustainability: These materials are non-toxic, fire-resistant, and recyclable, offering effective insulation that reduces energy consumption by keeping buildings cooler in summer and warmer in winter.

- Eco-friendly: Glass and mineral wool are often produced using recycled glass and other materials, minimizing waste and supporting a circular economy.

3. Silicate-Based Paints and Coatings

- Silicate Paints:

- Potassium silicate-based paints (also known as mineral paints) are made from natural silicate minerals, such as kaolin (a type of clay), quartz, and feldspar.

- Sustainability: These paints are eco-friendly because they contain no volatile organic compounds (VOCs), are highly durable, and have a long lifespan. They also offer moisture-regulating properties, improving building energy efficiency.

- Benefits: Silicate paints are resistant to mold and fungus, reduce the need for frequent repainting, and are non-toxic to human health and the environment.

4. Environmentally Friendly Building Blocks

- Rammed Earth:

- Rammed earth construction, using a mixture of sand, clay, and silicate-rich aggregates, is a low-energy building method that uses locally available materials.

- Eco-benefit: The technique promotes sustainable architecture by reducing the environmental impact of transporting materials and cutting down on construction waste. It also provides natural thermal insulation.

- Silica Bricks:

- Silica bricks, made from high-purity silica sand, are used in furnaces and kilns due to their high melting point and resistance to thermal shock.

- Sustainability: These bricks are durable, have a long lifespan, and are made from abundant, naturally occurring materials, making them eco-friendly for high-temperature applications.

5. Eco-Friendly Glass and Ceramics

- Glass Production:

- Silica sand is the primary raw material used in the production of glass, including recycled glass products. Glass has high durability, is recyclable, and can be used in energy-efficient windows and facades.

- Sustainability: The recycling of glass significantly reduces energy use and CO₂ emissions compared to producing new glass from raw materials. Moreover, low-emissivity glass (using silica-based coatings) improves building energy efficiency by controlling solar heat gain.

- Ceramics:

- Silica-based ceramics, made from kaolin, quartz, and feldspar, are used in eco-friendly floor tiles, bricks, and sanitary ware.

- Eco-benefit: These ceramics are durable, require less energy for firing, and can be made using local materials, reducing transportation-related emissions. They also have low maintenance needs and long lifespans, contributing to sustainability.

6. Soil Remediation and Environmental Cleanup

- Silica-Based Materials for Filtration:

- Activated silica is used in water filtration systems to remove contaminants and purify drinking water. It is also used in oil spill cleanup because it can absorb oils and other contaminants from water bodies.

- Eco-benefit: Silica-based filtration systems are natural, sustainable alternatives to synthetic chemicals and can be used for large-scale environmental cleanup projects.

7. Carbon Sequestration

- Carbon Capture in Silicate Minerals:

- Minerals like olivine (a silicate mineral) have the ability to capture and store CO₂ through a natural process called weathering. This process converts CO₂ into solid minerals, effectively sequestering carbon.

- Sustainability: Using silicate minerals for carbon sequestration offers a long-term solution to reducing greenhouse gases in the atmosphere, supporting efforts to combat climate change.

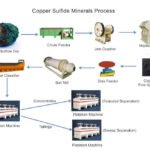

8. Waste Recycling and Upcycling

- Recycling Silicate Waste:

- Silicate-rich by-products, such as slag from metal smelting or silica dust from mining operations, can be repurposed for use in construction materials, cement production, and road paving.

- Circular Economy: By recycling and upcycling these materials, industries can reduce waste, minimize the need for virgin raw materials, and lower energy consumption, contributing to a more sustainable industry.

Conclusion

Silicate minerals play a crucial role in sustainable and eco-friendly construction and industrial applications. They are used in a variety of products, from cement and concrete to insulation materials, paints, and glass, that promote energy efficiency, reduce environmental impact, and support recycling. Additionally, silicate minerals contribute to carbon sequestration and environmental cleanup, helping mitigate the environmental footprint of industrial activities. Through their widespread use and sustainable management, silicate minerals are essential for a more sustainable future in both the construction and industrial sectors.