Sulfate minerals, such as gypsum (CaSO₄·2H₂O), barite (BaSO₄), and anhydrite (CaSO₄), play a crucial role in the mineral processing of ores. Their chemical properties, solubility, and reactivity influence various processing techniques like flotation, leaching, and hydrometallurgical extraction. Below is a detailed exploration of how sulfate minerals impact these methods.

1. Flotation Process and Sulfate Minerals

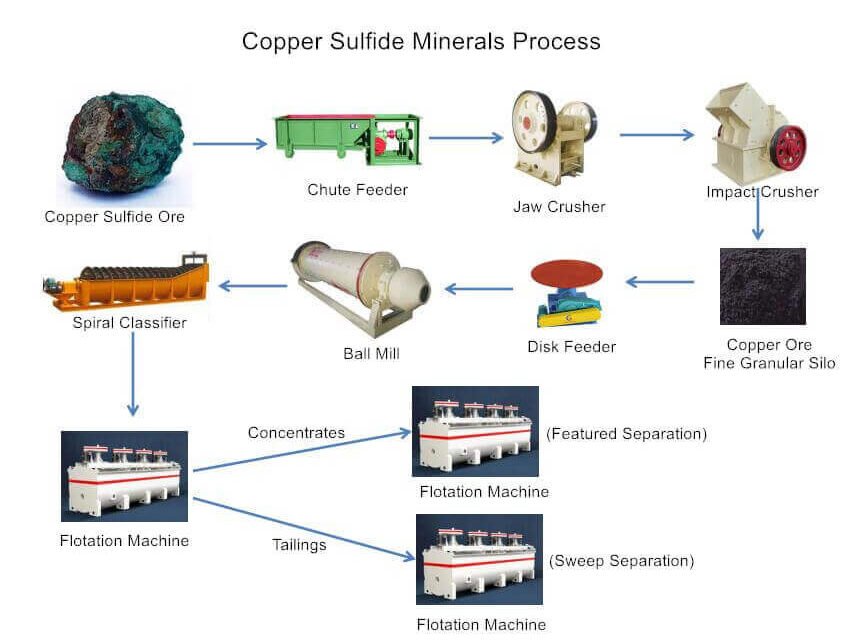

Flotation is a key separation technique in mineral beneficiation, where air bubbles are introduced to a pulp of finely ground ore, causing hydrophobic minerals to adhere to the bubbles and float to the surface, while hydrophilic minerals sink.

Influence of Sulfate Minerals:

- Flotation Reagents:

- Sulfate minerals can interfere with flotation if not properly managed. Some sulfate ions may react with flotation reagents, leading to poor selectivity and loss of mineral recovery.

- For example, barite (BaSO₄) is heavily influenced by ionic flotation collectors (anionic collectors), which are used to separate barite from gangue minerals. The sulfate component in barite forms stable complexes with the collector, which can reduce the efficiency of separation.

- Gypsum can also impact flotation by causing increased reagent consumption due to its high solubility in acidic media, leading to unwanted interactions with flotation reagents.

- Challenges in Sulfate Mineral Flotation:

- The presence of gypsum and anhydrite in ores can lead to slime coatings that hinder the flotation process by making surfaces more hydrophilic, which is the opposite of what is desired in flotation.

- Scale formation is a common issue when sulfate minerals like barite precipitate in flotation circuits, causing blockages in pipes and affecting flotation cell performance.

- Mitigation:

- Flotation reagents can be tailored to specifically target sulfate minerals for separation. For instance, cationic collectors can help float sulfates like barite, while anionic collectors can be used for other minerals.

- Water conditioning agents (like dispersants or pH modifiers) are employed to prevent gypsum and other sulfate minerals from coating ore surfaces.

Example Applications:

- Barite flotation: In heavy media separation (for barite), specialized flotation techniques are used to separate it from silicate gangue by adjusting the pH and using sodium oleate as a collector.

- Copper-gold flotation: Sulfate minerals like gypsum can negatively affect the flotation of copper and gold ores by forming slimes. To combat this, the pH is often adjusted to optimize mineral separation.

2. Leaching Process and Sulfate Minerals

Leaching is a process where valuable metals are dissolved from the ore into a solvent (usually acidic or basic) to separate them from gangue minerals. It is widely used in hydrometallurgy for the extraction of metals like gold, copper, and nickel.

Influence of Sulfate Minerals:

- Acid Leaching:

- Sulfate minerals such as pyrite (FeS₂), gypsum (CaSO₄), and barite (BaSO₄) can either complicate or enhance the leaching process, depending on the ore and chemical conditions.

- Pyrite is a primary source of acid mine drainage (AMD) because, when exposed to oxygen and water, it oxidizes to form sulfuric acid (H₂SO₄), which lowers pH and enhances the dissolution of metals like copper and gold.

- In acid leaching, gypsum can dissolve, contributing to the formation of calcium sulfate (CaSO₄), which may further influence the pH and ion concentration in the leach solution.

- Barite and Gypsum Impact:

- Barite can present a problem in copper and gold leaching because it is relatively insoluble in both acidic and alkaline solutions. In ores where barite is present, it can impede the leaching of valuable metals by occupying valuable leaching areas.

- Gypsum in gold cyanidation circuits can result in the formation of jarosite (KFe₃(SO₄)₂(OH)₆), which consumes cyanide and reduces gold recovery.

- Challenges in Leaching:

- Precipitation of gypsum in acidic solutions can affect the efficiency of the leaching process, requiring higher acid consumption to maintain the desired pH.

- The formation of iron sulfate (FeSO₄) during pyrite oxidation can lead to scaling problems and reduce the leaching rate in copper or zinc extraction.

- Mitigation:

- Control of pH is critical during acid leaching. For instance, in copper leaching, maintaining a slightly acidic pH helps control the dissolution of pyrite and minimizes gypsum formation.

- Selective leaching reagents can be used to target specific metal components while minimizing the dissolution of unwanted sulfate minerals.

- Pre-treatment steps, such as roasting or chemical oxidation, are employed to remove or modify sulfate minerals before the leaching stage.

Example Applications:

- Copper extraction: In copper leaching, the presence of gypsum can lead to the formation of unwanted calcium sulfate deposits, which complicates the extraction process. To mitigate this, calcium sulfate is often neutralized before leaching.

- Gold cyanidation: Sulfate minerals, such as gypsum and barite, may consume cyanide in gold ore processing, reducing overall gold recovery rates.

3. Other Mineral Processing Methods and Sulfate Mineral Influence

(a) Smelting and Roasting

- Impact of Sulfate Minerals:

- In the smelting process, sulfate minerals such as gypsum and barite can lead to the formation of slag, which contains sulfates and other impurities.

- Roasting of sulfide ores, such as pyrite, produces sulfur dioxide (SO₂), which then reacts with oxygen to form sulfur trioxide (SO₃), ultimately leading to the formation of sulfuric acid.

(b) Ion Exchange and Solvent Extraction

- Impact of Sulfate Minerals:

- In solvent extraction, the presence of sulfate ions (SO₄²⁻) can interfere with the separation of metals, as they might form insoluble salts with certain metal ions.

- In ion exchange, sulfate ions can compete with other metal ions, affecting the efficiency of the process.

Conclusion

Sulfate minerals significantly impact the flotation, leaching, and other mineral processing techniques, influencing the efficiency and selectivity of extraction processes. The chemical reactivity of sulfate minerals, such as pyrite, barite, and gypsum, can complicate the beneficiation of valuable ores by affecting reagent interactions, pH control, and formation of byproducts like acid mine drainage and gypsum scaling.

However, with appropriate process optimization, including adjustment of pH, selective reagent use, and pre-treatment methods, the negative impact of sulfate minerals can be mitigated, enhancing the overall efficiency and sustainability of mineral processing. As the demand for environmentally conscious mining practices grows, developing innovative technologies for managing sulfate mineral impacts will be crucial for the future of the industry.

Hashtags

#SulfateMinerals #MineralProcessing #FlotationTechniques #LeachingProcesses #MineralSeparation #SulfateOre #OreBeneficiation #LeachingChallenges #FlotationChallenges #MineralExtraction #SulfateProcessing #OrePurification #MineralSeparationTechniques #MiningTechnology #Hydrometallurgy #SulfateImpact #MineralConcentration #OreRefining #SulfateOreProcessing #EcoMining