- Extraction Process of Silicate Minerals:

- Physical Separation: Silicate minerals are primarily extracted through physical methods like crushing, grinding, and flotation, which separate the valuable minerals based on their physical properties (e.g., size, density, and electrical conductivity).

- Smelting and Roasting: While silicate minerals like feldspar and mica may undergo some heat treatment (e.g., roasting) to enhance their properties for industrial use, they do not require extensive chemical processes for extraction.

- Chemical Leaching: In some cases, acidic or basic solutions may be used for selective extraction or processing (e.g., sodium carbonate or hydrofluoric acid in certain processes), but this is less common compared to other mineral groups.

- Extraction of Other Mineral Groups:

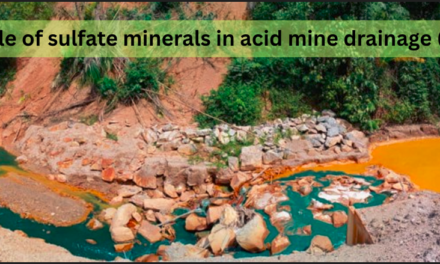

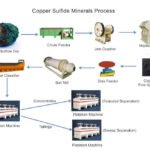

- Sulfide Minerals (e.g., Copper, Lead, Zinc):

- Roasting and Smelting: Sulfide ores typically require high-temperature roasting (to remove sulfur) and smelting to extract the metals. For instance, copper sulfide ores are heated in a furnace to produce copper metal.

- Hydrometallurgical Processing: Sulfide ores are often processed using hydrometallurgical methods such as leaching, where chemicals (e.g., cyanide for gold or sulfuric acid for copper) are used to dissolve the metal.

- Oxide Minerals (e.g., Iron, Aluminum):

- Bauxite (for aluminum) undergoes Bayer’s process (a chemical treatment with sodium hydroxide) to separate alumina from the bauxite.

- Iron ores (hematite, magnetite) are processed in blast furnaces, where smelting with coke removes oxygen to produce liquid iron.

- Carbonate Minerals (e.g., Limestone, Dolomite):

- Carbonate ores are commonly heated (calcined) to produce a metal oxide, as in the extraction of lime from limestone (calcium carbonate) using a high-temperature kiln.

- Sulfide Minerals (e.g., Copper, Lead, Zinc):

- Key Differences in Extraction Techniques:

- Physical vs. Chemical: Silicate minerals primarily rely on physical separation techniques, while other groups like sulfides and oxides often require more intensive chemical processing (e.g., roasting, smelting, leaching).

- Temperature Requirements: Silicate minerals generally require lower temperatures in comparison to high-temperature smelting used in sulfide and oxide extraction.

- Waste and Environmental Impact: The extraction of silicate minerals typically produces less hazardous waste compared to the toxic fumes and waste slag generated in sulfide and oxide mining, making their extraction less environmentally intensive.

Conclusion

Silicate minerals are extracted through simpler physical methods (e.g., crushing, grinding, flotation) with minimal reliance on chemical processing compared to other mineral groups like sulfides, oxides, and carbonates. While silicates often require mild heating or slight chemical treatments, metals from other groups typically need more intensive chemical and thermal processes such as roasting, smelting, and leaching. The difference in extraction methods reflects the varying chemical compositions of these mineral groups, with silicates being relatively more stable and requiring less energy-intensive methods for their processing.