The presence of silicate minerals in metal ores significantly influences the beneficiation and refining processes due to their chemical, physical, and mineralogical properties. Silicates are often gangue minerals (non-valuable minerals) in ore bodies, and their separation and removal can be challenging but crucial for efficient metal extraction. Here’s how silicate minerals affect beneficiation and refining:

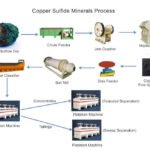

1. Impact on Beneficiation (Ore Concentration)

Beneficiation refers to the process of separating valuable minerals from the gangue (waste) minerals, and silicate minerals can pose several challenges in this stage:

- Physical Properties of Silicates:

- Hardness: Silicate minerals like quartz and feldspar are generally hard, making them difficult to crush and grind. This results in higher energy consumption during size reduction and increases costs.

- Density Differences: Silicates, particularly those like feldspar and quartz, have similar densities to many valuable ores. This makes it challenging to separate silicates from valuable minerals using gravity-based methods (e.g., jigs or spirals).

- Separation Difficulty:

- Flotation Challenges: Silicate minerals often have similar surface chemistry to the valuable minerals, which makes froth flotation (a commonly used technique for separating minerals based on surface properties) less efficient. The separation of silicate minerals from valuable minerals may require specialized reagents or more complex flotation processes.

- Magnetic Separation: Many silicates, such as quartz, are non-magnetic, making them difficult to separate using magnetic methods. Only certain silicate minerals like magnetite (iron silicate) can be separated magnetically.

- Slurry and Water Management:

- Waste Generation: The presence of silicate minerals in ore increases the amount of tailings produced, as they are typically not valuable and must be discarded. This adds to the volume of material that needs to be managed in terms of waste storage and disposal.

- Water Contamination: Silicate-rich ores often generate large volumes of water when processed, and the slurry created can be difficult to treat, leading to challenges in water management during beneficiation.

2. Impact on Refining (Metal Extraction)

Refining involves the extraction of pure metals from ores, and silicate minerals affect this process in several ways:

- Smelting and High Temperatures:

- Increased Energy Requirements: Silicate minerals generally have high melting points, meaning they require higher temperatures in smelting processes. This increases the energy consumption and cost of extracting metals, especially when silicate minerals are present in large quantities in the ore.

- Formation of Slag: During smelting, silicates in the ore often combine with impurities to form slag, which must be removed. The presence of silicate minerals in the ore may result in the production of a larger volume of slag, which increases the material that needs to be processed and disposed of.

- Fluxing Agents: To facilitate the smelting of silicate-rich ores, fluxing agents (e.g., limestone or soda ash) are often added to help break down silicate minerals and form fluid slag. This adds to the complexity and cost of the refining process.

- Chemical Reactions:

- Acid Leaching: Silicate ores may require the use of acid leaching (e.g., sulfuric acid for copper or gold) to extract the metal. However, silicates are often resistant to acidic attack, meaning they may not readily dissolve, which can limit the efficiency of the process. Additional treatments or reagents may be required to increase the extraction efficiency.

- Reduction Reactions: Silicate minerals, especially those containing aluminum or iron, can interfere with the reduction reactions used to extract metals like copper, zinc, or iron. These reactions may require additional steps, such as roasting or carbon reduction, to remove silicates and other gangue minerals.

- Impact on Purity:

- Contamination: Silicate minerals can contribute to the impurity of the extracted metal, especially if they are not completely separated during beneficiation. This can reduce the quality of the final product and require additional refining steps, such as electrorefining, to improve metal purity.

- Efficiency of Extracting Target Metals:

- Low Recovery Rates: Silicate minerals may reduce the metal recovery rates in both pyrometallurgical and hydrometallurgical processes due to inefficient separation and the formation of unwanted compounds. This makes the extraction process more labor-intensive and less profitable.

3. Environmental and Economic Impacts

- Increased Waste Generation: Silicate-rich ores tend to produce large volumes of tailings and slag, both of which must be stored or disposed of properly. This contributes to environmental challenges such as water contamination and land degradation.

- High Operational Costs: The presence of silicate minerals often leads to higher energy consumption, additional reagent costs, and increased wear and tear on equipment during both beneficiation and refining stages. These factors increase the overall operational costs.

- Environmental Management: Proper management of silicate-rich waste (tailings and slag) requires effective systems to prevent contamination of local water resources and ensure long-term land reclamation. Without proper management, these materials can lead to acid mine drainage, heavy metal contamination, and other environmental issues.

4. Mitigation Strategies

To address the challenges posed by silicate minerals in beneficiation and refining:

- Advanced Separation Techniques: Use of more efficient separation technologies such as froth flotation with selective reagents, magnetic separation, and electrostatic separation.

- Improved Smelting and Fluxing: Optimizing fluxing agents to help silicate minerals break down more easily and improve the smelting process.

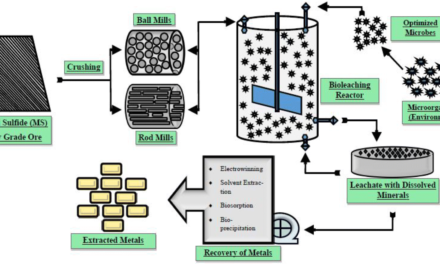

- Bioleaching: Exploring bioleaching techniques, which use microorganisms to extract metals from silicate ores, can reduce the need for high-temperature processes and chemicals.

- Water Recycling: Implementing closed-loop water systems and efficient tailings management practices to minimize environmental impact and conserve water.

Conclusion

The presence of silicate minerals in metal ores complicates both the beneficiation and refining processes by increasing energy requirements, reducing recovery rates, and producing large amounts of waste. Their inert nature, hardness, and tendency to form complex compounds during smelting or leaching pose challenges for extracting metals efficiently and economically. However, with the application of advanced technologies, efficient separation methods, and proper waste management practices, the challenges of silicate-rich ores can be mitigated.