Modern technology is transforming mining operations by improving efficiency, safety, and sustainability across the industry. Innovations in automation, artificial intelligence (AI), robotics, data analytics, and other technological advancements are helping to reduce costs, enhance productivity, and mitigate risks. Here’s how modern technology is making mining safer and more efficient:

1. Automation and Robotics

- Autonomous Vehicles and Equipment:

- Self-driving trucks, haulage systems, and drills are becoming common in open-pit and underground mines. These vehicles can operate without human drivers, allowing for 24/7 operation without the risks associated with human fatigue or error.

- Benefits:

- Increased efficiency through continuous, optimized hauling and drilling operations.

- Safety improvements by removing workers from hazardous environments, such as in blasting zones or toxic gas exposure areas.

- Reduced operating costs over time due to automation and the reduction of labor requirements.

- Robotic Exploration and Drilling:

- Robotic drills can reach more challenging areas of a mine and conduct more precise, controlled drilling. This enhances the accuracy of exploration, ensuring that resources are mined more effectively.

- Drones and autonomous rovers are being used for site surveying, exploration, and mapping, providing real-time data without requiring human presence in risky or hard-to-reach areas.

2. Advanced Data Analytics and AI

- Predictive Analytics:

- AI and machine learning algorithms can analyze large amounts of data to predict equipment failures, identify patterns in ore deposits, and optimize mine operations.

- Maintenance predictions can detect potential breakdowns before they happen, reducing downtime and extending the lifespan of machinery.

- Operational efficiency can be increased by continuously monitoring performance and adjusting operations in real-time to avoid inefficiencies.

- Ore Grade Prediction:

- AI-driven models analyze geological data and drilling results to predict ore grades more accurately. This allows mining operations to optimize extraction processes, reducing waste and increasing recovery rates.

- In situ ore measurement and real-time analysis ensure that mining operations focus on the highest-value ore bodies, minimizing waste and maximizing profitability.

- Environmental Monitoring:

- Advanced data systems can track and monitor environmental impacts in real-time, including emissions, dust levels, and water quality. This helps companies comply with environmental regulations and reduce their ecological footprint.

- Remote sensing technology (e.g., satellite imaging, LiDAR) helps monitor large areas for environmental compliance, including identifying potential hazards like acid mine drainage or surface subsidence.

3. Internet of Things (IoT)

- Connected Equipment:

- Mining companies are using IoT sensors to monitor equipment performance and environmental conditions. Sensors attached to machines can detect vibrations, temperatures, pressures, and other factors that may indicate a potential failure.

- Fleet management systems use real-time data to track the location, fuel consumption, and health of autonomous and manned equipment. This allows for better coordination, minimizing idle time and reducing costs.

- Smart Mines:

- In smart mines, IoT technology connects all elements of the operation—from machinery to workers to environmental conditions—creating an interconnected network that enhances decision-making.

- Wearable technologies such as smart helmets and vests can communicate with the IoT system, tracking worker health, location, and safety in real-time, providing alerts for any potential dangers such as toxic gas leaks, falling objects, or extreme environmental conditions.

4. Artificial Intelligence (AI) and Machine Learning

- AI for Mineral Exploration:

- AI algorithms are now used to analyze geological data (such as seismic surveys and core samples) to identify potential mineral deposits more efficiently and accurately than traditional methods.

- AI-powered software is helping geologists model ore bodies and predict their size, shape, and composition with greater precision, enabling more informed decisions about where to drill or mine.

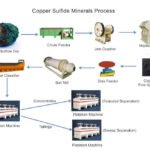

- Mining Process Optimization:

- AI and machine learning models can optimize mining processes such as blasting, drilling, and extraction by predicting the best methods for reducing energy use and improving material recovery.

- Load optimization is used to determine the optimal distribution of ore to minimize transport costs and maximize processing efficiency.

5. Virtual Reality (VR) and Augmented Reality (AR)

- Training and Simulation:

- VR and AR technologies are being used to train miners in a safe and controlled environment. Workers can practice operations, equipment handling, and emergency response protocols without the risks of actual mining sites.

- Simulations can recreate dangerous or complex mining scenarios, allowing workers to practice in various virtual environments before facing them in real life.

- Remote Assistance:

- AR headsets and wearable devices are used to provide real-time guidance and assistance to workers in the field. Experts can offer remote support and instructions via augmented visuals or live video feed, improving safety and troubleshooting efficiency.

- Virtual Mine Design:

- VR can be used for mine planning and design, allowing engineers and geologists to walk through virtual mine plans before they are implemented. This allows for better risk assessment and safety planning before actual excavation begins.

6. Advanced Blasting Technologies

- Controlled Blasting Techniques:

- Modern explosives and blasting technologies, like fragmentation analysis, help optimize the size of mined ore, reduce waste, and ensure that rocks are broken in a way that is safer for both equipment and workers.

- Wireless blasting systems allow for more precise detonation, improving timing and safety by ensuring that no workers are nearby at the time of blasting.

- Blasting Optimization Software:

- Software tools help optimize blasting patterns, taking into account geological factors to ensure that energy is used efficiently and safely.

7. Remote and Autonomous Operations

- Remote Monitoring:

- Many mining operations are adopting remote operations centers that monitor and control mining equipment and processes from a distance. This allows operations in remote or hazardous locations to continue without the need for workers to be physically present.

- Autonomous Underground Mining:

- Autonomous vehicles and robotic systems are being used for underground mining, allowing for safer and more efficient extraction in confined spaces where human presence is hazardous.

- Automated ventilation and air quality control systems are improving the safety of underground workers by ensuring that air circulation is optimized, reducing the risks of exposure to harmful gases.

8. Sustainable Mining Practices

- Energy Efficiency:

- Mining operations are integrating more energy-efficient technologies, such as electric vehicles (EVs) for hauling, solar energy, and energy storage systems to reduce reliance on fossil fuels.

- Waste heat recovery systems and carbon capture technologies are being used to reduce the environmental impact of mining processes and lower emissions.

- Water Management:

- Water recycling systems, desalination technologies, and smart water management systems are being deployed to reduce water usage in mines and improve water quality by preventing contamination of local water sources.

9. Health and Safety Technologies

- Wearables:

- Smart helmets and wearable devices can monitor a worker’s physiological status (heart rate, fatigue levels, body temperature) and send alerts if they are in danger, preventing health issues like heat stress or fatigue-related accidents.

- Personal gas detectors are used to alert workers to dangerous gas levels (e.g., methane, carbon monoxide), improving safety in underground mines.

- Safety Monitoring Systems:

- Automated systems can monitor conditions like air quality, noise, and vibration in real time, ensuring that workers are operating in safe environments.

- Robotic systems equipped with cameras and sensors can inspect hazardous areas, such as collapsed tunnels or areas with toxic gases, to assess conditions before human workers are sent in.

10. Supply Chain Optimization and Blockchain

- Supply Chain Efficiency:

- Mining companies are using blockchain technology to track the movement of minerals from the mine to the market. This ensures that supply chains are transparent, and materials are sourced responsibly.

- Digital platforms help optimize the supply chain, tracking inventory, monitoring logistics, and reducing delays and inefficiencies.

Conclusion

Modern technology is dramatically improving the efficiency, safety, and sustainability of mining operations. From automation and AI-driven optimization to advanced safety monitoring systems and remote operations, technology is transforming how mines operate and manage resources. By integrating these technologies, mining companies can reduce operational costs, improve environmental stewardship, enhance worker safety, and increase overall productivity.