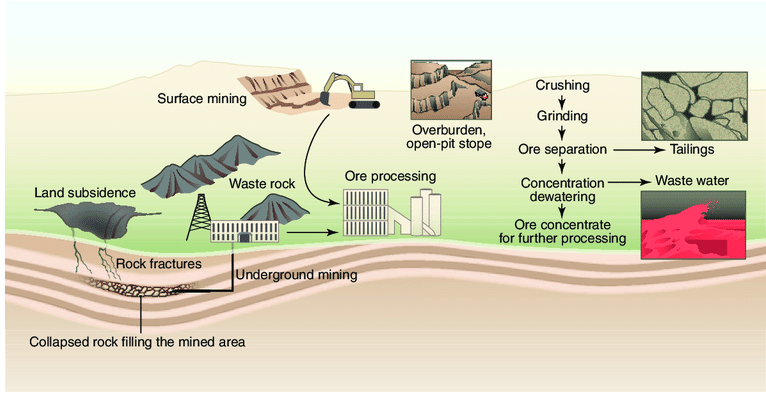

Waste management in mineral processing is a critical aspect of reducing environmental impact and ensuring sustainable operations. Mining and mineral processing generate a variety of waste materials, which need to be handled responsibly to minimize their adverse effects on the environment and human health. Here’s an overview of how waste is managed in mineral processing, the types of waste produced, and the environmental challenges involved.

Types of Waste in Mineral Processing

- Tailings

- What they are: Tailings are the leftover materials after the valuable minerals have been extracted from the ore during the processing stages (crushing, grinding, flotation, etc.). They consist of finely ground rock, water, and residual chemicals used in separation processes.

- Volume: Tailings represent the largest waste stream from mineral processing, often accounting for 90% or more of the total volume of material processed.

- Composition: They may contain water, fine particles, heavy metals, residual chemicals (e.g., cyanide or sulfuric acid), and sometimes radioactive elements (particularly in uranium or rare earth mining).

- Slag

- What it is: Slag is a byproduct of pyrometallurgical processes, like smelting, where impurities from ores (such as silicates, oxides, or sulfides) are separated from the metal. Slag forms as a result of the combination of impurities with fluxing agents at high temperatures.

- Uses: While slag is sometimes reused in construction (e.g., in road building or cement production), it still represents a potential waste if not managed properly.

- Dust and Airborne Emissions

- What they are: Dust and particulates are generated during crushing, grinding, transport, and handling of ore and waste materials. Also, smelting and roasting processes release gases like sulfur dioxide (SO₂), carbon dioxide (CO₂), and nitrogen oxides (NOx), which can contribute to air pollution.

- Composition: Dust may contain particulate matter, heavy metals, and chemicals used in processing. Airborne emissions may contain hazardous gases and vapors.

- Spent Reagents

- What they are: Chemicals used in mineral processing, such as flotation agents, leaching agents (e.g., cyanide), and other solvents, often become waste after use.

- Environmental Impact: Spent reagents can be toxic or harmful if not disposed of properly. For example, residual cyanide from gold extraction can leach into groundwater or surface water, causing contamination.

- Water Waste

- What it is: Water used in mineral processing (e.g., for flotation, leaching, or dust suppression) becomes contaminated with fine particles, chemicals, and residual metals.

- Challenges: Water waste must be treated before discharge, as it may contain harmful substances that could pollute surrounding ecosystems and water sources.

Waste Management Strategies in Mineral Processing

- Tailings Management

- Storage: Tailings are usually stored in tailings dams or tailings ponds, where they can settle and separate into layers of solids and water. The water is typically recycled back into the process, while the solids are left behind.

- Thickening and Filtering: Tailings can be thickened to reduce their volume, or they can be filtered to remove excess water, producing drier waste material for more manageable storage or potential reuse.

- Paste Tailings: In some cases, paste tailings (a thick slurry) are used instead of traditional slurry to reduce the environmental risks of tailings dam failure. Paste tailings have a higher solids content and lower water content, reducing the risk of seepage and failure.

- Geotechnical Stability: Ensuring the structural stability of tailings dams is a major challenge, as dam failures can lead to catastrophic environmental disasters, as seen in past mining accidents (e.g., the Samarco tailings dam disaster in Brazil).

- Recycling and Reuse of Waste

- Slag Recycling: Slag can sometimes be recycled or reused in the production of cement, concrete, or aggregates for construction. It can also be used in certain chemical processes.

- Metal Recovery: Precious or valuable metals, like gold, silver, or copper, often remain in waste streams such as tailings or slag. Metal recovery techniques such as flotation, leaching, or electrochemical methods can be employed to recover these metals, reducing the need for further mining and refining.

- Recycling Chemicals: In some cases, chemicals used in processing, such as cyanide, can be recovered and reused, reducing environmental risks and improving economic efficiency.

- Water Management

- Water Treatment: Water used in processing must be treated before discharge to remove contaminants. Techniques include flocculation (adding chemicals to make particles settle), reverse osmosis, ultrafiltration, and neutralization (to remove acidic or alkaline residues).

- Water Recycling: Many mineral processing operations aim to recycle water within the system, reducing the need for fresh water intake and minimizing wastewater generation.

- Dust Control and Emission Management

- Dust Suppression: Water sprays, wetting agents, and dust collectors (e.g., cyclones or baghouses) are used to control airborne dust generated during mining and processing.

- Emission Control: Gases produced during smelting and refining (such as sulfur dioxide) are captured using flue gas desulfurization systems or scrubbers. The gas is then either converted to safer compounds or neutralized before being released.

- Reagents Management

- Recovery of Reagents: Technologies are being developed to recover and recycle chemicals used in processing, such as cyanide, reducing the environmental impact of their disposal.

- Alternative Reagents: The development of more environmentally friendly reagents (e.g., less toxic leaching agents for gold extraction) is another strategy to reduce harmful waste.

Environmental Challenges in Mineral Processing Waste Management

- Tailings Dam Failures

- Risk of collapse: Tailings dams are a major environmental concern. Failures can result in the catastrophic release of tailings into surrounding areas, affecting local ecosystems, wildlife, and human populations. Managing the long-term stability and integrity of these dams is an ongoing challenge.

- Seepage: The leakage of chemicals or metals from tailings into groundwater can lead to contamination of drinking water and local ecosystems. Securing tailings dam areas and reducing seepage is essential to minimize environmental impacts.

- Chemical Contamination

- Cyanide and Mercury: Mining operations, particularly in gold mining, use toxic chemicals like cyanide and mercury to extract metals. These chemicals can be harmful to aquatic life and humans if they are not handled properly during processing and disposal.

- Heavy Metals: Tailings and slag may contain heavy metals (e.g., arsenic, lead, cadmium) that can leach into the environment and cause soil and water contamination. Proper containment and treatment are required to mitigate these risks.

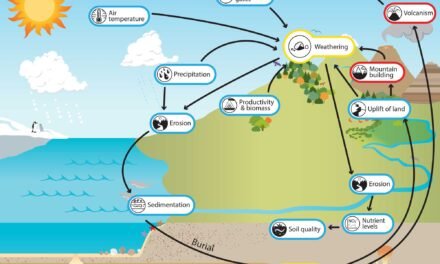

- Acid Mine Drainage (AMD)

- What it is: Acid mine drainage occurs when sulfide minerals in ore react with air and water, forming sulfuric acid. This acid can leach heavy metals from surrounding rock, creating toxic runoff that can contaminate rivers and groundwater.

- Mitigation: Preventing AMD involves controlling the exposure of sulfide minerals to air and water, treating contaminated water, and neutralizing acids through lime treatment or other means.

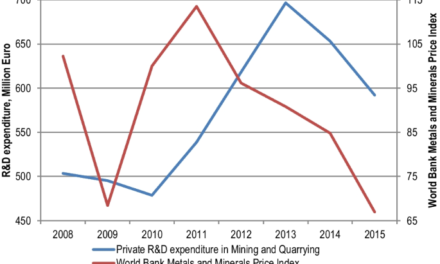

- Energy and Water Use

- High Energy Consumption: Many mineral processing techniques (especially pyrometallurgy and electrometallurgy) are energy-intensive, contributing to high greenhouse gas emissions and global warming.

- Water Scarcity: Water usage in mining is a growing concern, particularly in arid regions. Mining companies are under increasing pressure to reduce water consumption and manage wastewater effectively.

- Social and Community Impact

- Health Risks: Communities near mining operations may be exposed to environmental pollutants, such as dust, heavy metals, and chemicals, which can pose health risks like respiratory issues, skin diseases, and long-term cancer risks.

- Displacement and Conflict: Mining activities can lead to the displacement of local communities, destruction of livelihoods (especially agriculture), and conflicts over land rights and resource usage.

Conclusion

Waste management in mineral processing is a significant challenge that requires a balance between efficient mineral extraction and minimizing the environmental and social impacts of waste. Effective waste management strategies, such as recycling, reusing, and treating waste materials, along with adopting cleaner technologies, are key to mitigating environmental risks. However, the mining industry faces ongoing challenges related to tailings disposal, chemical contamination, and the long-term sustainability of waste management practices. To ensure that mineral processing is sustainable, continual innovation and the adoption of best practices in waste management are essential.