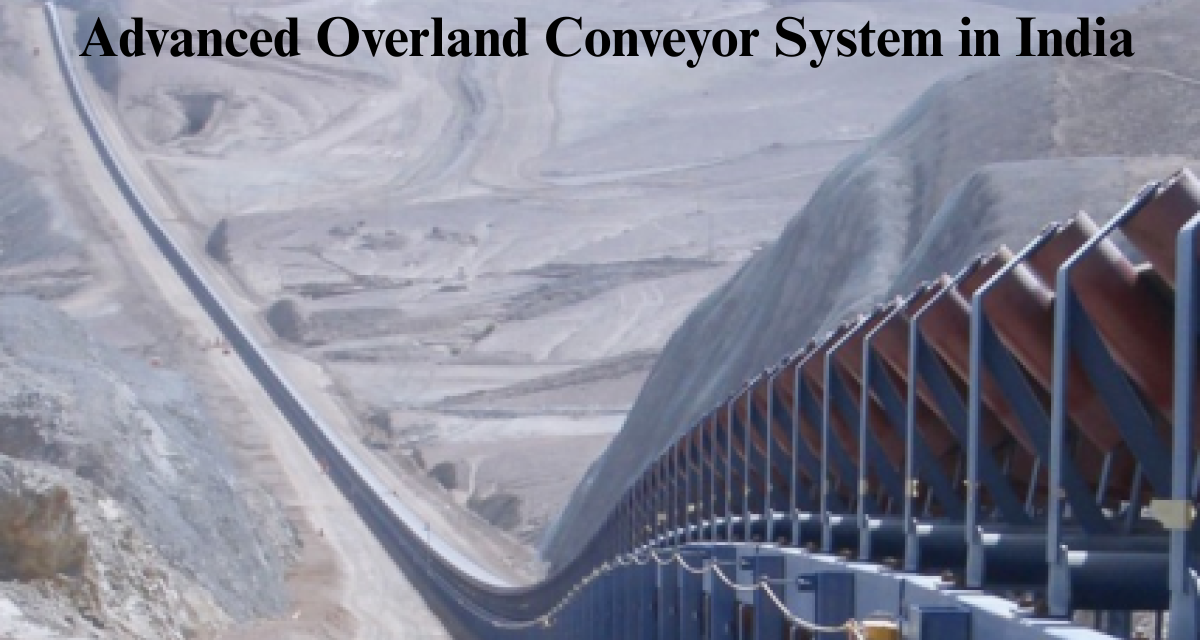

TAKRAF GmbH has engineered and installed a 19-kilometer overland conveyor system for the Utkal Alumina project in Tikri, Raigada, India. This installation stands as the longest single-flight conveyor system within Indian territory to date. The system is designed to transport bauxite from the mines to a 4.5 million tonnes per annum alumina plant, traversing highly undulating terrain throughout its route.

The conveyor system’s design addresses the challenges posed by the topography and its extensive length. It features head and tail drives, along with multiple, tight compound horizontal and vertical curves. The longer conveyor is equipped with six 850 kW drives at the tail end and four at the head end, while the shorter conveyor utilizes two 850 kW drives at the head end. Each conveyor includes a fail-safe hydraulic disc brake at the tail end and a take-up winch with a capstan brake arrangement at the head end.

To accommodate the hilly terrain at the intermediate transfer point between the two conveyors, the conveyor drive and take-up area are mounted on a portal steel structure. These lightweight yet high-strength structures provide the necessary design flexibility to navigate the challenging landscape. For maintenance accessibility, approach roads and a mine road have been established along the entire conveyor length, with cage ladders provided on elevated structures.

This project underscores TAKRAF’s expertise in delivering advanced material handling solutions tailored to complex environmental conditions. The successful implementation of this overland conveyor system not only enhances the efficiency of bauxite transportation for the Utkal Alumina project but also sets a benchmark for future large-scale conveyor installations in India.