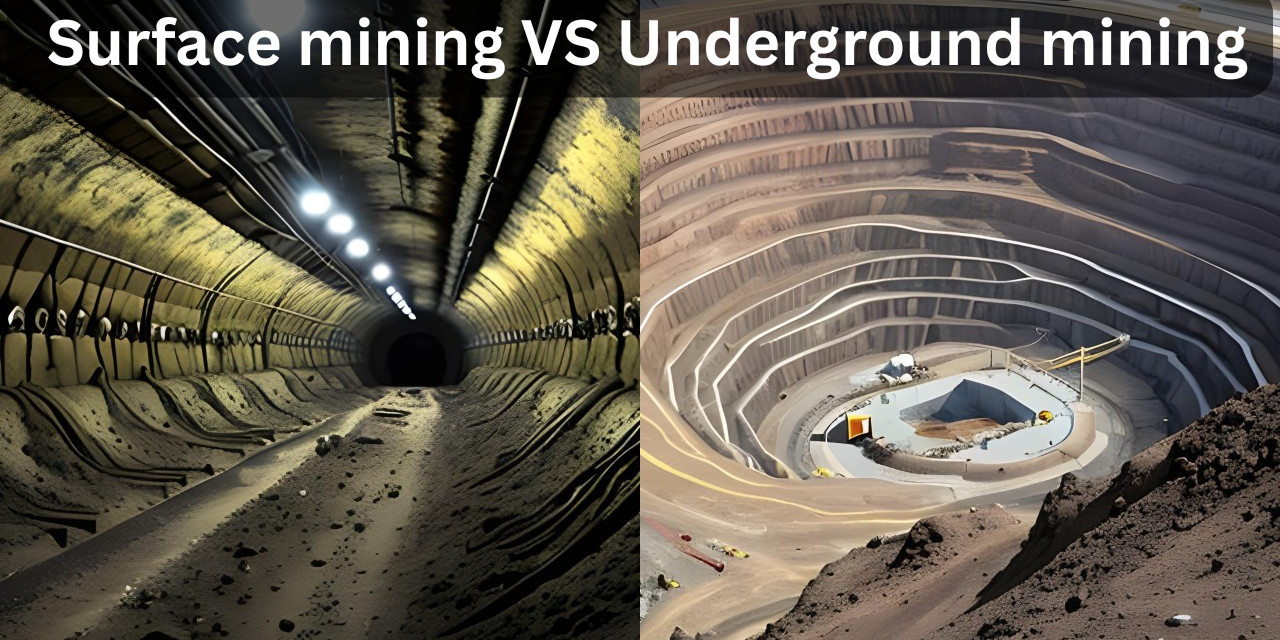

Surface mining and underground mining are the two primary methods used to extract minerals and ores from the earth. The key differences between these two mining methods lie in the depth of the ore body, the type of deposit being mined, and the impact on the environment. Here’s a detailed breakdown:

1. Mining Method

- Surface Mining:

- Definition: Surface mining involves removing the overburden (soil, rock, and other materials) that lies above the ore body to expose and extract the minerals. It is used for deposits located close to the surface.

- Techniques:

- Open-pit mining: A step-like excavation method used when the ore body is at or near the surface and is spread over a wide area.

- Strip mining: Often used for coal or minerals in horizontal layers, where successive strips of overburden are removed to expose the ore.

- Mountaintop removal: Used for coal extraction, where the tops of mountains are blasted off to expose coal seams.

- Placer mining: Involves extracting minerals like gold from alluvial deposits by washing and sifting through sediments.

- Underground Mining:

- Definition: Underground mining involves digging tunnels or shafts into the earth to reach ore bodies located deeper below the surface. It is used when the ore body is too deep to be extracted by surface mining methods.

- Techniques:

- Drift mining: Horizontal tunnels (drifts) are used to access ore bodies that are located beneath the earth’s surface.

- Shaft mining: Vertical shafts are drilled down to reach deeper ore bodies, with tunnels (levels) connecting different parts of the deposit.

- Room and pillar mining: Common in coal and salt mining, where miners leave pillars of ore to support the roof while extracting the surrounding material.

- Cut and fill mining: Used when extracting ore from steeply dipping ore bodies, where the void left after extraction is filled with waste materials to prevent collapse.

2. Depth of Ore Body

- Surface Mining: Primarily used for shallow ore bodies or deposits close to the surface. If the ore is located at depths of up to 100-200 meters, surface mining is generally more economical.

- Underground Mining: Employed for ore bodies located deep beneath the surface, often at depths greater than 200 meters. It is necessary when the ore is too deep to be reached by surface mining techniques.

3. Cost of Operation

- Surface Mining:

- Lower initial costs: Surface mining tends to have lower startup costs because it doesn’t require building complex tunnels or shafts.

- Economies of scale: It allows for the extraction of larger volumes of material with the use of large machinery, making it more cost-effective for large ore bodies.

- High operational costs for reclamation: While it’s cheaper to mine initially, surface mining often requires significant costs for land reclamation and restoration after mining is complete.

- Underground Mining:

- Higher initial costs: Underground mining involves constructing tunnels or shafts, which can be very expensive and time-consuming.

- Higher operating costs: Due to the need for ventilation, safety measures, and the use of specialized equipment, underground mining is typically more expensive to operate.

- Limited scale: Underground operations tend to have a lower volume of material extracted compared to surface mining, which can make them less efficient for large ore bodies.

4. Environmental Impact

- Surface Mining:

- More disruptive: Surface mining can cause significant environmental disruption. Large areas of land are cleared, leading to deforestation, habitat destruction, and soil erosion.

- Water contamination: The removal of overburden can lead to the contamination of nearby water sources through runoff of chemicals or heavy metals.

- Visual impact: Surface mining often leaves behind large pits or waste heaps, which can degrade the landscape and may require long-term restoration efforts.

- Underground Mining:

- Less surface disruption: Underground mining has a smaller footprint on the surface and typically causes less direct environmental disturbance compared to surface mining.

- Subsidence risk: However, underground mining can lead to subsidence (the sinking or collapse of the ground above the mined area), which can damage infrastructure and cause surface instability.

- Water management: Underground mining may require extensive water management systems, as groundwater can seep into tunnels, requiring pumping and treatment.

5. Safety and Working Conditions

- Surface Mining:

- Safer working conditions: Surface mining is generally considered safer because workers are not exposed to the dangers of cave-ins or toxic gas buildup.

- Exposure to elements: However, workers are still exposed to harsh weather conditions, heat, dust, and noise.

- Underground Mining:

- Riskier conditions: Underground mining poses significant safety risks, including cave-ins, rockfalls, and exposure to harmful gases (like methane in coal mines).

- Ventilation requirements: A key challenge in underground mining is maintaining proper ventilation to prevent the buildup of toxic gases and ensure workers have access to fresh air.

- More specialized equipment: Underground mining requires specialized equipment for excavation, material handling, and safety.

6. Extraction Efficiency

- Surface Mining:

- Higher extraction rates: Surface mining typically allows for the extraction of large quantities of ore at a relatively fast pace due to the use of large-scale machinery like excavators, haul trucks, and draglines.

- Efficient for large, shallow deposits: It is most efficient for large, horizontally spread deposits with shallow depths.

- Underground Mining:

- Lower extraction rates: Underground mining is less efficient in terms of volume, as the amount of material that can be extracted is more limited and slower.

- High selectivity: However, underground mining is better suited for deeper ore bodies or ore bodies that are too irregular or fragmented for surface mining.

7. Ore Recovery

- Surface Mining:

- Higher recovery rates: Surface mining generally results in higher recovery rates because large volumes of material can be extracted and processed. However, it may also result in the removal of waste rock that could have contained valuable materials.

- Underground Mining:

- Selective mining: Underground mining is often more selective, targeting specific ore bodies or veins. This can lead to more efficient recovery of valuable ores, but there may be more waste material left behind.

- Sub-level mining: In some cases, underground mining methods like sublevel stoping or cut and fill can result in higher recovery rates due to better control over the ore body.

8. Impact on Local Communities

- Surface Mining:

- Displacement of communities: Large surface mining projects often require relocating communities, especially when the mining site is in populated areas or agricultural land.

- Noise and dust: The noise, dust, and traffic associated with surface mining can have an adverse impact on nearby communities.

- Underground Mining:

- Less disruption: While underground mining tends to have less direct impact on surface communities, there can still be noise from mining equipment, air quality issues, and the potential for subsidence affecting nearby structures.

Conclusion

- Surface Mining is ideal for shallow, large ore bodies with low overburden. It is more cost-effective in terms of capital expenditure, allows for faster extraction, and is generally safer, but it can have severe environmental impacts.

- Underground Mining, on the other hand, is better suited for deeper, more confined ore bodies. It has higher costs due to its complex nature but is more environmentally responsible on the surface and can extract ores that surface mining cannot reach.