Beneficiation of carbonate ores involves a range of techniques aimed at increasing the concentration of the desired mineral while removing unwanted impurities or gangue. Since carbonate ores, such as limestone, dolomite, and calcite, are primarily composed of carbonates (CO₃²⁻), the beneficiation methods differ slightly based on the nature of the ore and its intended industrial application (e.g., for construction, metallurgy, or chemical uses).

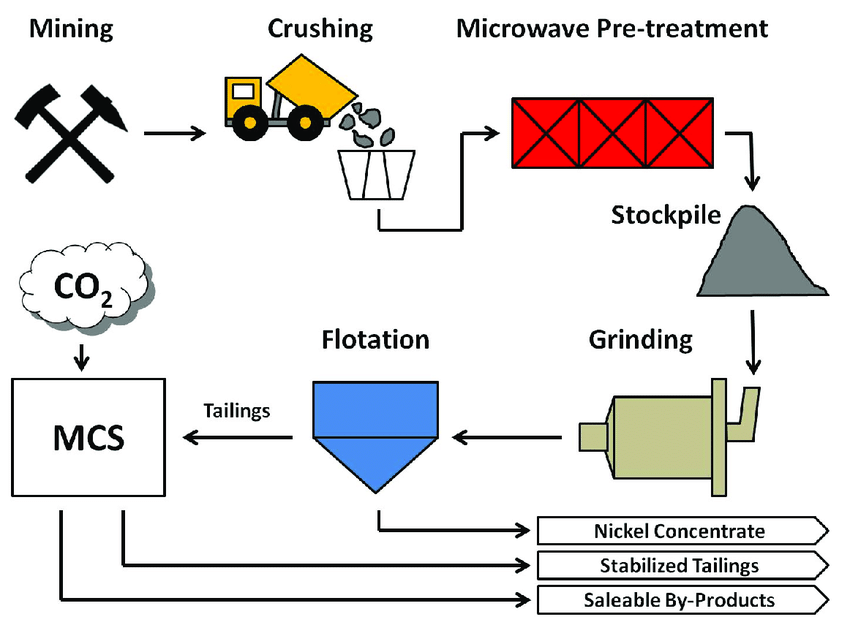

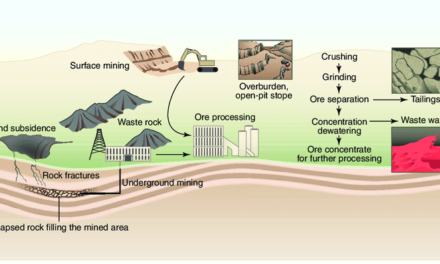

1. Crushing and Screening

- Initial Size Reduction: The first step in beneficiation is typically crushing the ore into smaller sizes to increase the surface area for further processing. This is followed by screening to separate different-sized particles. This method is essential for preparing the ore for subsequent processing stages, whether that be grinding, flotation, or leaching.

- Application: This is used for all carbonate ores and is a standard first step in beneficiation to prepare for more specific treatment.

2. Gravity Separation

- Principle: Gravity separation utilizes the difference in density between the carbonate minerals and gangue minerals. Heavier particles (e.g., dolomite or calcite) will settle faster in a water medium, while lighter impurities (e.g., silica) will be washed away.

- Techniques:

- Jigging: A form of gravity separation in which pulsed water flow creates differential settling based on particle size and density.

- Shaking tables: Involves shaking the ore on a table to facilitate the separation of dense minerals from lighter gangue.

- Application: This method is particularly effective for ores that have a notable difference in density between the carbonate mineral and the gangue.

3. Flotation

- Principle: Flotation is a separation process where the ore is treated with reagents that selectively alter the surface properties of the mineral particles, making the desired minerals hydrophobic (water-repellent) and allowing them to float, while the gangue minerals remain hydrophilic (water-attracting) and sink.

- Reagents: For carbonate ores, anionic collectors (such as fatty acids or their salts) and frothing agents are commonly used to facilitate flotation.

- Application: Flotation is particularly useful for dolomite ores and when carbonate minerals are associated with silicate minerals, which need to be separated.

4. Magnetic Separation

- Principle: Magnetic separation exploits differences in the magnetic properties of minerals. While carbonate minerals themselves are generally non-magnetic, magnetic minerals such as iron oxide or magnetite may be present as impurities.

- Application: This method is used when carbonate ores are associated with magnetic impurities. For example, limestone ores with iron oxide contamination can benefit from this method.

5. Leaching

- Principle: Leaching involves the use of chemicals (usually acids) to selectively dissolve the desired metal or mineral from the ore. The acid reacts with the carbonate mineral to break it down, while other impurities remain behind.

- Techniques:

- Acid Leaching: This is commonly used for carbonate ores containing metals like copper or zinc. Sulfuric acid or hydrochloric acid is used to dissolve the metal while leaving behind gangue minerals such as silica or clay.

- Calcination: In some cases, carbonate ores are subjected to calcination (heating to high temperatures), where they decompose to form metal oxides and release carbon dioxide (CO₂), effectively separating carbonates from other elements. This method is particularly relevant to lime production from limestone.

- Application: Leaching is typically used for ores where carbonate minerals are associated with valuable metallic elements like copper, zinc, or magnesium.

6. Froth Flotation (for Calcite and Dolomite)

- Principle: This method is similar to traditional flotation but optimized for calcite and dolomite ores, which can be tricky to separate from each other or from other minerals.

- Reagents: Specific chemicals like sodium oleate and kerosene may be used to enhance the flotation of calcite or dolomite.

- Application: Especially useful in dolomite beneficiation, where the separation of dolomite from other carbonate minerals (such as calcite) is necessary.

7. Calcination and Carbonation

- Principle: Calcination involves heating carbonate minerals like limestone to a temperature where they decompose to form lime (CaO) and release carbon dioxide. This is a thermal treatment method that is often used when lime production or other calcium-based products are the goal.

- Applications:

- Lime production: Limestone is calcined at high temperatures to produce quicklime (CaO), which is then used in construction, steelmaking, or environmental applications.

- Carbonation: After calcination, the resulting lime may be exposed to carbon dioxide (CO₂) to form calcium carbonate (CaCO₃) again, which is often used in industrial applications like paper production, plastic manufacturing, and soil treatment.

8. Acid Treatment

- Principle: This is particularly useful for the beneficiation of magnesite (a magnesium carbonate mineral). In this method, acid treatment dissolves unwanted impurities (such as silica) and leaves behind the desired magnesium product.

- Application: Used to refine magnesite ores to produce magnesium for various industrial uses, including alloy production and chemical processes.

9. Calcitic and Dolomitic Limestone Beneficiation

- Principle: Beneficiating limestone to create high-purity calcitic or dolomitic limestone typically involves size classification, washing, and acid treatment. For example, calcitic limestone (mainly CaCO₃) is processed to remove impurities like clay and silica, resulting in a more valuable product for cement production.

- Application: Ensures the production of high-quality lime or dolomitic limestone for use in industries like steelmaking or cement manufacturing.

Conclusion

The most effective beneficiation techniques for processing carbonate ores depend on the specific characteristics of the ore, including the mineral composition and the intended use of the final product. The most common methods include crushing and screening, gravity separation, flotation, magnetic separation, leaching, and calcination.