Specialty Mining refers to a set of techniques and processes used to extract materials that are typically more challenging to access or require specialized equipment or methods. Unlike conventional mining methods, which are often used for large-scale extraction of common resources like coal, iron ore, and copper, specialty mining is applied to unique or hard-to-reach deposits that demand more precise, customized approaches.

Key Features of Specialty Mining:

- Targeted Resources:

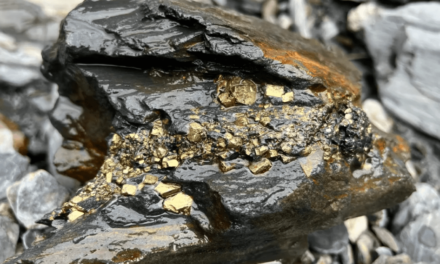

Specialty mining is often used to extract rare or unconventional resources, such as precious metals (e.g., gold, silver), rare earth elements (REEs), diamonds, or minerals in remote or difficult-to-access locations. - High Precision:

The techniques used in specialty mining are often more precise and tailored to specific deposits. Methods like borehole mining, solution mining, and selective extraction are typical. These methods ensure that only the desired material is extracted with minimal waste. - Advanced Technology:

Specialty mining requires advanced technologies like automated drilling, remote sensing, in-situ recovery (ISR), and real-time monitoring. These innovations make it easier to access hard-to-reach minerals and manage complex ore bodies. - Smaller-Scale Operations:

Compared to conventional mining, which is typically large-scale and involves the extraction of large volumes of ore, specialty mining operations are often smaller and more localized. This can be due to the limited availability or high-value nature of the resources being extracted. - Environmental Considerations:

Specialty mining often places a strong emphasis on minimizing environmental impact. Techniques such as in-situ leaching (used for uranium and copper extraction) and borehole mining (which involves less surface disruption) are more environmentally friendly than traditional methods like open-pit or underground mining.

Examples of Specialty Mining:

- Borehole Mining:

A technique that uses high-pressure water jets to extract valuable minerals from underground deposits with minimal surface disruption. - Solution Mining:

Often used for extracting salt, potash, and uranium, this method involves dissolving minerals in water and pumping the resulting solution to the surface. - In-Situ Recovery (ISR):

A method used for extracting uranium, copper, and other metals by injecting a solvent into the ore body and bringing the metals back to the surface via wells.

Specialty mining is increasingly becoming important for industries relying on rare and critical materials, and it’s also better suited for minimizing ecological footprints in areas that conventional mining cannot easily access. Would you like to explore some specific applications of specialty mining in industries like REE extraction?