The presence of native elements in ore deposits can significantly impact various mineral extraction techniques, including flotation, smelting, and other methods like gravity separation and leaching. Native elements, such as gold, silver, copper, and platinum, often occur in a pure, uncombined state, but they may also be associated with other minerals or metals that complicate their extraction. Here’s how native elements can influence each of these mineral extraction techniques:

1. Flotation

Flotation is primarily used to separate sulfide ores from gangue minerals, and it works well for many native elements that are associated with sulfide minerals. However, the presence of native elements can have both positive and negative effects on the flotation process:

Influences of Native Elements on Flotation:

- Native Copper and Silver:

- Native copper and native silver are relatively easy to float compared to other minerals because they are already in their pure metallic form and do not require significant chemical modification. These metals are typically more hydrophobic (water-repellent), which is desirable for flotation.

- However, native copper can sometimes cause problems during flotation because it tends to oxidize easily, forming a copper oxide layer that can affect the flotation efficiency. This can require additional treatment or the use of specific reagents to prevent oxidation.

- Native Gold:

- Native gold is generally non-reactive and hydrophobic, so it can be easily separated through flotation. However, it’s usually found in association with sulfide minerals (like pyrite or arsenopyrite), so flotation may require careful reagent management to avoid co-flotation with these unwanted minerals. Gold often requires specialized depressants to prevent it from floating with sulfides.

- Reagents such as xanthates and dithiophosphates are typically used to selectively float gold, while sodium cyanide can be used to depress the flotation of unwanted gangue minerals.

- Platinum and Palladium:

- Native platinum or platinum-group metals (PGMs) can be difficult to float because they have a very high density and may sink rather than float. They often require specific collector chemicals to enhance their flotation properties.

- PGMs can be found with other sulfide minerals, and if present in fine particles, they may need specialized flotation circuits to ensure selective separation.

Conclusion for Flotation:

The presence of native elements in flotation can complicate the process when dealing with impurities or associated sulfides, but native metals like gold, copper, and silver often float well due to their hydrophobic properties. Adjustments to flotation reagents and conditions are often necessary to optimize recovery and prevent native elements from co-floating with other materials.

2. Smelting

Smelting is a high-temperature process used to extract metals from their ores, especially for elements like copper, platinum, and sometimes gold. The presence of native elements can have a profound impact on the smelting process:

Influences of Native Elements on Smelting:

- Native Gold:

- Gold is often found in its native state, either alone or mixed with quartz or sulfide minerals. Since native gold is already in its pure metallic form, it requires minimal smelting. However, gold is often associated with base metal sulfides, which need to be separated in the smelting process.

- Gold may be separated from impurities by cupellation, where lead or other impurities are oxidized and absorbed by the cupel, leaving gold behind.

- Native Copper:

- Native copper can be easily smelted, but it often requires flux to combine with other impurities and form a slag. For example, copper can be smelted in a furnace with silica, which forms a slag that removes iron, silica, and other contaminants.

- Oxidation can occur if the copper is exposed to air at high temperatures, leading to the formation of copper oxide, which must be reduced by additional smelting processes to obtain pure copper.

- Platinum and PGMs:

- Platinum-group metals (PGMs) are typically co-smelted with other ores containing sulfide minerals, such as nickel and copper ores, in the platinum mining process. The metals are often extracted as part of a matte (a mixture of metal and sulfide), which is then subjected to further refining steps.

- The high melting point of platinum means that it requires specialized smelting conditions, and the presence of other elements can complicate the formation of pure platinum.

- Native Silver:

- Silver is typically extracted from native silver ores by smelting, but the metal is often found with impurities such as lead, gold, or copper. Cupellation is often used to remove these impurities. Silver smelting usually involves reducing the ore with a carbon or charcoal source.

Conclusion for Smelting:

The presence of native elements like gold, copper, and silver simplifies the smelting process to some extent since these metals are already in a relatively pure state. However, the presence of impurities like sulfides or base metals can complicate smelting, requiring additional steps or refining techniques like cupellation or oxidation-reduction reactions to separate valuable metals.

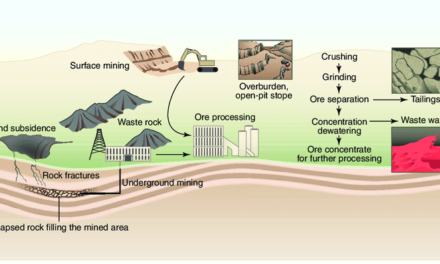

3. Other Extraction Techniques: Gravity Separation and Leaching

In addition to flotation and smelting, techniques such as gravity separation and leaching are often used for native elements.

Gravity Separation:

- Gravity separation is commonly used for native elements that are present in alluvial deposits or have a high specific gravity, such as native gold, native copper, and native platinum. These metals can easily be separated from lighter gangue materials by using gravity-based methods like panning, sluicing, shaking tables, or jigging.

- The high density of native metals makes them easy to concentrate in these processes, which work by exploiting the differences in density between the metal and surrounding rock or soil.

Leaching:

- Leaching is often used to extract native metals from oxide ores or low-grade ores.

- Cyanide leaching is commonly used for gold and silver extraction from ores containing the metals in oxide or sulfide forms. Native gold is often leached with cyanide to remove impurities and increase recovery.

- Acid leaching can be used to extract native copper from copper ores, especially oxide copper ores. In this process, copper is dissolved in dilute sulfuric acid, leaving behind impurities as insoluble residues.

Conclusion for Gravity Separation and Leaching:

Gravity separation is a very effective method for native elements like gold and copper when they occur in native or placer deposits. Leaching provides a more efficient method for extracting metals like gold and silver from low-grade ores, but its effectiveness depends on the form of the metal. Native elements generally undergo less intensive leaching processes compared to sulfide ores because they are already in their pure metallic state.

Conclusion

The presence of native elements like gold, silver, copper, and platinum can influence extraction techniques in various ways:

- Flotation can be straightforward for native metals due to their hydrophobic nature but may require adjustments to prevent native elements from co-floating with sulfide gangue minerals.

- Smelting of native metals is often simpler because these metals are already in their pure metallic form, but impurities or associated minerals may require additional steps like cupellation or reduction processes.

- Gravity separation works efficiently for native metals in placer deposits due to their high density.

- Leaching of native metals is often less complex than for other ores, but certain metals (like gold and copper) may still require the use of reagents such as cyanide or sulfuric acid.

In conclusion, native elements generally require less intensive processing than other ores but can still pose challenges due to the presence of impurities or associated minerals that need to be separated.

Hashtags

#NativeElements #MineralExtraction #FlotationTechniques #SmeltingProcess #MineralSeparation #NativeMetals #OreProcessing #MetalExtraction #MiningTechnology #MineralRefining #OreBeneficiation #SmeltingAndRefining #NativeElementExtraction #MetalRecovery #MineralProcessingTech #FlotationAndSeparation #ExtractionTechniques #MineralConcentration #MetallurgicalProcessing #NativeMineralProcessing